Toyota, one of the leading automobile manufacturers in the world, has always been committed to ensuring the highest quality and safety standards for their vehicles. With a strong focus on customer satisfaction and continuous improvement, Toyota has implemented various measures and processes to ensure that their vehicles meet and exceed industry standards.

Rigorous Testing and Quality Control

One of the primary ways in which Toyota ensures the quality and safety of their vehicles is through rigorous testing and quality control processes. Before a Toyota vehicle is released to the market, it undergoes extensive testing in various conditions to ensure its performance, reliability, and safety. This includes testing the vehicle’s durability, handling, braking, and safety features.Like as the impact of vehicle quality on safety performance.

Toyota also has a comprehensive quality control system in place, which involves regular inspections and audits at every stage of the manufacturing process. This ensures that any potential issues or defects are identified and addressed before the vehicles are delivered to customers.

Advanced Technology and Innovation

Toyota is known for its commitment to innovation and the use of advanced technology in their vehicles. This commitment extends to ensuring the quality and safety of their vehicles as well.

Toyota vehicles are equipped with advanced safety features such as collision avoidance systems, lane departure warning, adaptive cruise control, and automatic emergency braking. These features not only enhance the safety of the vehicle but also help in preventing accidents and reducing the severity of injuries in case of a collision.

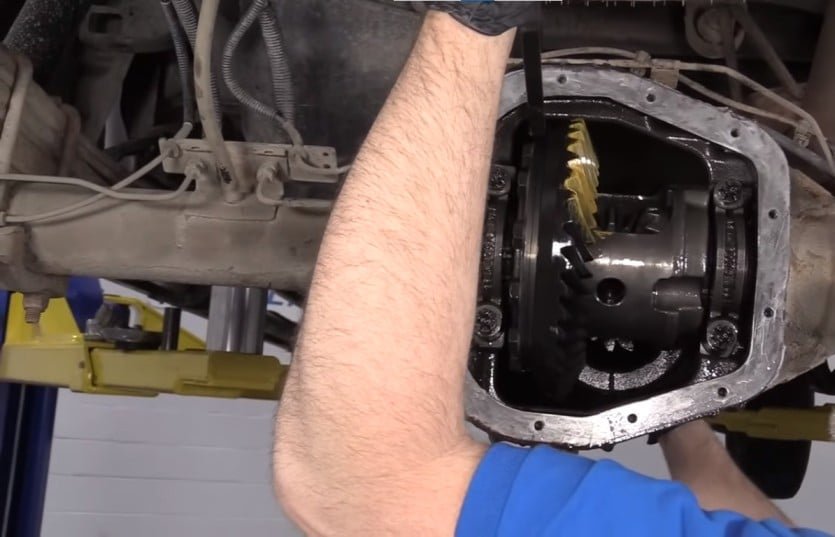

In addition to safety features, Toyota also utilizes advanced manufacturing processes and materials to ensure the quality and reliability of their vehicles. This includes the use of high-strength steel, advanced welding techniques, and precision engineering to create vehicles that are not only safe but also built to last.

Continuous Improvement and Customer Feedback

Toyota’s commitment to quality and safety goes beyond the manufacturing process. The company also places great importance on continuous improvement and customer feedback.

Toyota actively encourages its customers to provide feedback on their vehicles, including any safety concerns or issues they may have encountered. This feedback is invaluable in identifying potential areas for improvement and addressing any safety-related issues promptly.

Furthermore, Toyota has a robust system in place for collecting and analyzing data from various sources, including customer feedback, vehicle inspections, and crash tests. This data is used to identify trends, patterns, and potential safety risks, allowing Toyota to take proactive measures to address them.

Collaboration with Industry and Regulatory Bodies

Toyota recognizes the importance of collaboration with industry and regulatory bodies to ensure the quality and safety of their vehicles. The company actively participates in industry forums, conferences, and working groups to stay updated on the latest safety standards and best practices.

Toyota also works closely with regulatory bodies and government agencies to ensure compliance with safety regulations and to contribute to the development of new safety standards. This collaboration helps Toyota stay at the forefront of safety innovation and ensures that their vehicles meet or exceed the required safety standards in different markets. Read more about toyota’s quality, durability and reliability here.

Conclusion

Toyota’s commitment to quality and safety is evident in the measures and processes they have in place. Through rigorous testing, advanced technology, continuous improvement, and collaboration with industry and regulatory bodies, Toyota ensures that their vehicles are not only of the highest quality but also meet the highest safety standards. As a result, customers can have confidence in the safety and reliability of Toyota vehicles.